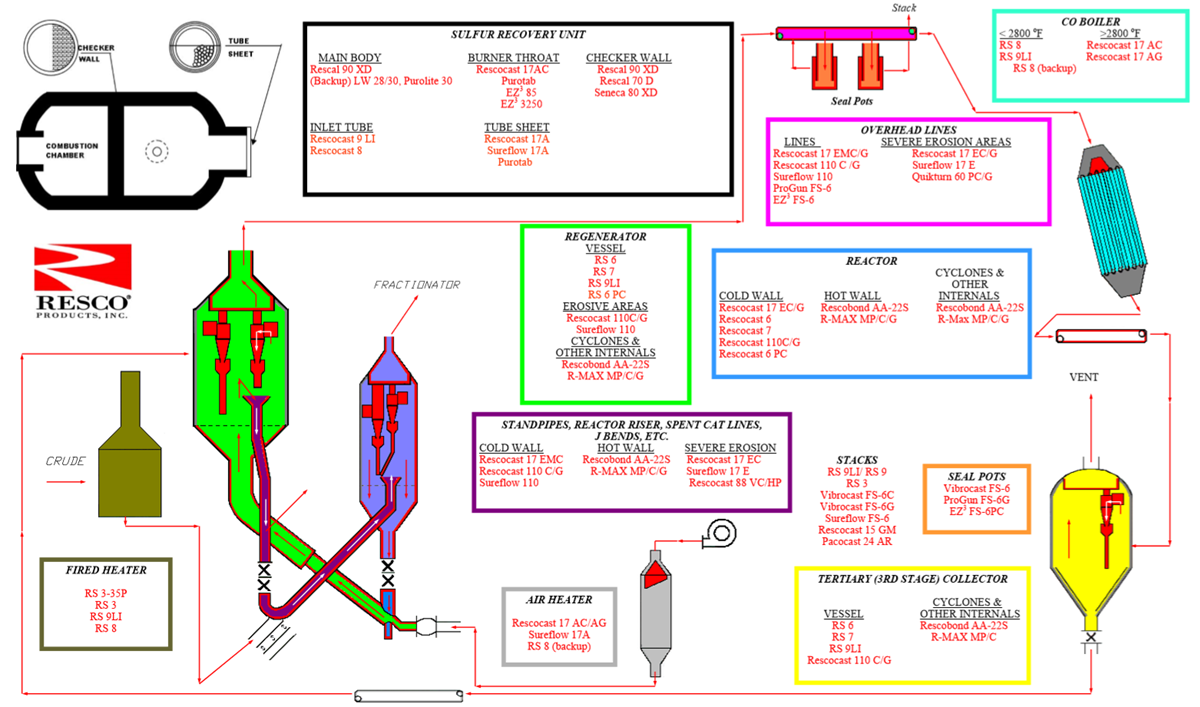

Fluidized Catalytic Cracking Unit Refractory Products (FCCU)

Articles

PRODUCT RECOMMENDATIONS - FCC UNIT

The Rescobond family of products are “Chemically Bonded”, air-setting refractory castables that are prepared for use by simply adding water. They develop a quick set and can be heated shortly after installation without a controlled dryout schedule to provide the fastest ”back online” time possible. Rescobond’s chemically bonded system provides adherence to existing refractory, making it a highly effective monolithic repair material.

The Rescocast family of “Extreme Service Castables” is a complete line of specialty castables blended for specific application and performance requirements. Formulations are available for hydrogen and/or carbon monoxide-rich reducing atmospheres, for low thermal conductivity and high resistance to thermal shock, for critical wear areas, in high abrasion/erosion applications and wherever a high ratio of strength to insulating value is required.

Resco Products, "Insulating Castables" are available, ranging in density from 25 to 95 pounds a cubic foot. All products are manufactured under careful supervision to strict technical standards. Several products are well suited for use in difficult application areas, including reducing atmospheres.

Most products are available in a “PC” (Pumpcast) version for placement by “pumping, casting, or shotcreting.

Sureflow products are self flowing and leveling products having low water requirements and require no vibration. These products include conventional and low cement formulations.

Products for these applications are not limited to those indicated in this brochure. Please contact your local Resco sales representative or Resco’s website for additional product information.

FCC Unit Refractory Products

|

is a premium, abrasion/erosion resistant chemically bonded castable, which has set the industry standard for performance and long service life throughout its range of applications. Rescobond AA-22S readily bonds to other refractory surfaces; it is ideal as a quick and easy patch/permanent patch for worn linings. Rescobond AA-22S offers the benefits of air-setting, low shrinkage and consistent results. Rescobond AA-22S is particularly effective in thin, metal-anchored and metal reinforced linings. |

|

|

RESCOCAST 110C & 110G |

are monolithics that combine strength and abrasion resistant qualities with low thermal conductivity, in a product that can be either cast or gunned. |

|

RESCOCAST 17AC & 17AG |

are 95% alumina, cement bonded monolithics designed for applications up to 3400°F (1870°C). The low iron & silica contents (<0.1% each), make them suitable for applications in hydrogen and/or carbon monoxide-rich reducing atmospheres. |

|

RESCOCAST 17EC, 17EPC & 17EG |

are Resco’s premium and most widely applied monolithics with an abrasion/erosion resistance of < 10cc loss for the cast and < 14cc loss for the gunited product. These cement bonded monolithics can be cast, vibra-cast, dry gunned, pumped or wet shotcreted. The Rescocast 17E series are the “specified” products in the industry. |

|

is a casting grade erosion resistant refractory, designed specifically for vibration casting. The physical properties define the product’s name…. Less than 8 cc abrasion/erosion loss and less than 8 “k” Value. |

|

|

RESCOCAST 17EMC & 17EMG |

have been developed by using a patented blend of raw materials. These monolithics were designed for lower thermal conductivity and high resistance to thermal shock |

|

high performance castable designed to provide maximum abrasion/erosion resistance and superior ease of application. The product’s zero-slump and soft “easy to install” texture, results in high handpack installation rates, while the low green to fired shrinkage of refractory translates into stronger, longer lasting service life. |

|

|

R-MAX C & G |

are 3200°F, low cement, high performance castables that are designed to exhibit very low abrasion/erosion loss and maximized physical properties. |

|

RESCOCAST RS-3005NS |

is a high purity alumina insulating castable. Vibration casting is the recommended installation method for this product. This product features a low thermal conductivity and a very high maximum temperature limit. The trace amounts of silica and iron oxide make this product ideal for use in carbon monoxide and hydrogen atmospheres especially at high temperatures. Available for hydrogen processing units, second stage ammonia reformers, etc. which require a high alumina, no silica product. |