BOF Refractory Linings

Articles

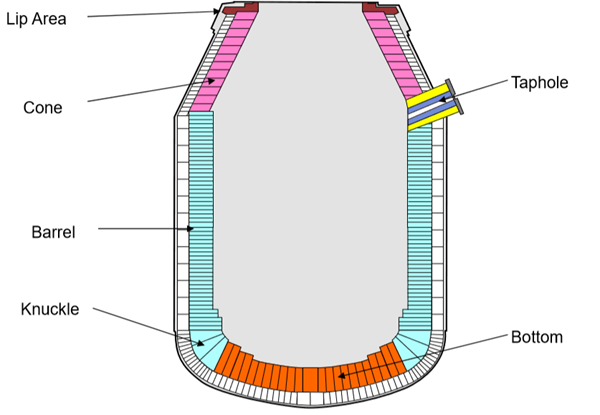

SAFETY LINING REQUIREMENTS

The safety lining in the BOF / Q-BOP is typically tasked to perform a single campaign potentially coving many years. Most shops utilize a single 9" safety bottom using skews in the knuckle or radial transition area of the bottom to the barrel. The barrel safety lining is usually 9" in thickness. Cone safety linings can be 6-9" in total thickness using standard key shapes or special parallelogram shapes to provide better fit. Mortar is generally used in laying the bottom safety lining and skews, but bricks in all other areas are usually laid dry.

| Safety Lining | ||

| Section | Brick | Mortar |

| Bottom | perecon | Permanente Mortar |

| Knuckle | Oxiline H | Permanente Mortar |

| Barrel | Oxiline H / Oxiline B / Nuline RS | Permanente Mortar |

| Cone | Oxiline H / Oxiline B / Nuline RS | Permanente Mortar |

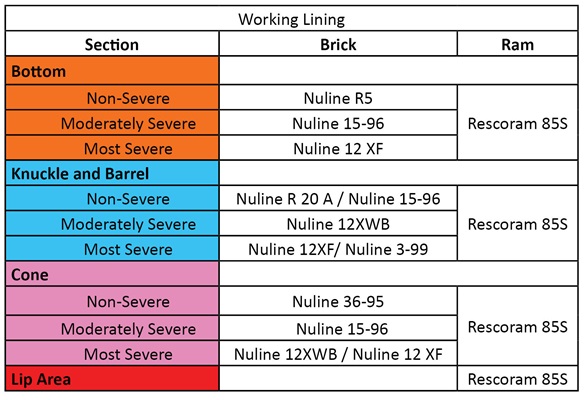

WORKING LINING REFRACTORIES IN BOF

The working lining must be designed to provide exceptional integrity for the life of the vessel usually ranging from many months to many years. This design must also be balanced so that uniform wear can be achieved and gunning maintenance kept to a minimum. The overall cost per ton is kept in mind in putting an entire package together. Bottom construction can range from a combination of keys, a single key-wedge, to the currently popular concentric ring design. Knuckle construction can run from simple keys laid horizontally, to precut wedge shapes, to key-arch-wedge shapes called radial knuckle skews that make the transition from the bottom to the barrel using single shapes in consecutive courses. Barrels usually consist of standard keys in lengths from 21”-33". Cone shapes can be standard keys to special parallelogram shapes. Tapholes can consist of special shapes or the concept of core drilling can be used to create an opening capable of having a taphole sleeve inserted and gunned around.

|

BRAND DESCRIPTION |

|

|

OXILINE H |

a burned high purity/high strength composition that offers very high strength as well as complete freedom from concerns for oxidation. |

|

OXILINE B |

a burned, tar-impregnated high purity/high strength composition that offers very high strength as well as complete freedom from concerns for oxidation. |

|

NULINE 15-96 |

a mid-level magnesite carbon product containing high purity sintered MgO and graphite and a dual metals addition. |

|

NULINE R 20 A |

a mid-level magnesite carbon composition containing a metal addition for oxidation resistance and strength enhancement |

|

RESCORAM 85S |

an 85% alumina, phos-bonded plastic material. |

|

NULINE 12 XF |

a premium magnesite carbon composition containing very high purity fused MgO and graphite and a dual metals addition for exceptional oxidation resistance and strength enhancement. |

|

Nuline 12 XWB |

a premium magnesite carbon composition containinga combination of sintered &fused MgO, graphite and a dual metals addition for exceptional oxidation resistance and strength enhancement. |

|

NULINE 3-99 |

a premium magnesite carbon product containing very high purity fused MgO and graphite and having significant dual metals additions providing the ultimate oxidation and strength enhancement. |

|

PERECON |

a burned 95% magnesia class brick that contains a special additive to achieve improved hydration resistance. |

|

METALKASED FEATURE |

This feature consists of gluing22 gauge steelto four sides of any brick shape. This provides enhanced brick-to-brick bonding as well as providing thermal expansion relief to the entire lining. |

|

PERMANENTE MORTAR |

a dry magnesite, air setting mortar. |

BOF TAPHOLE REFRACTORIES

RESCO promotes the concept of epoxied/ core drilled tapholes. Placement of an is opressed taphole (also available from RESCO) in this drilled opening results in excellent long-term integrity and freedom from steel penetration. This concept also speeds up the reline process by 4 hours or more and eliminates the need to handle large, heavy pieces and placing them in the proper alignment.